Material Testing Lab Quality: Browsing the Scientific Research of Material Characteristics

Wiki Article

Advancements in Material Testing Techniques: Insights From a Leading Material Testing Research Laboratory

You'll find exactly how non-destructive screening has actually evolved, explore emerging technologies in material analysis, and learn concerning novel approaches to assessing material buildings. By the end of this article, you'll have a better understanding of the cutting-edge techniques being utilized in product screening labs, equipping you with the understanding to make enlightened decisions about the products you function with.Innovations in Non-Destructive Checking

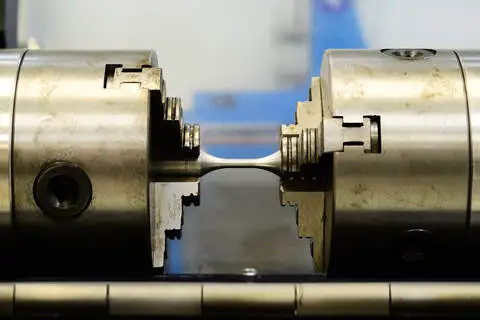

In this write-up, we will check out the most current advancements in non-destructive screening techniques that have been originated by our leading product screening research laboratory. Non-destructive testing (NDT) plays an important function in making certain the integrity and quality of materials without triggering any type of damages. With the consistent demand for even more efficient and accurate testing methods, our laboratory has been at the forefront of establishing ingenious methods.One of the noteworthy developments in NDT is the use of innovative imaging modern technologies. Our lab has actually effectively integrated high-resolution imaging techniques such as electronic radiography and calculated tomography into the screening procedure. These strategies enable accurate and comprehensive assessments of interior structures and parts, giving beneficial understandings right into any prospective issues or weak points.

Moreover, our research laboratory has also made significant progress in the area of ultrasonic testing. By utilizing state-of-the-art tools and sophisticated signal processing formulas, we have enhanced the accuracy and reliability of ultrasonic screening techniques. This allows us to identify and examine even the tiniest problems or gaps in materials, guaranteeing their integrity and safety.

Furthermore, our lab has been proactively researching and applying sophisticated electro-magnetic screening methods. By utilizing the power of electro-magnetic waves, we are able to examine and evaluate the homes of products without direct call. This non-contact method not only enhances the rate and effectiveness of screening but additionally reduces the danger of damages to sensitive elements.

Emerging Technologies in Product Analysis

Checking out emerging technologies in material analysis can give beneficial insights into the high quality and properties of products. Spectroscopic strategies like infrared spectroscopy and Raman spectroscopy are extensively utilized to recognize chemical bonds and useful teams in natural and inorganic products.One more emerging modern technology in product evaluation is X-ray diffraction (XRD) XRD is a powerful device that can figure out the crystal structure of a product, providing details about its atomic setup and crystalline phases. This strategy is especially beneficial in the research of metals, minerals, and ceramics, as well as in the recognition of unknown materials.

Enhancing Accuracy and Accuracy in Checking

To boost the precision and accuracy in screening materials, you can utilize sophisticated techniques and approaches. One efficient approach is using automated testing systems. These systems depend on computer-controlled devices that can carry out examinations with higher precision and uniformity contrasted to hand-operated testing. By removing human mistake, automated systems can make sure more dependable results. Additionally, using sophisticated sensing units and instrumentation can boost the precision of dimensions. High-resolution instruments can spot also the tiniest variances, permitting extra precise information collection. Calibration of tools is additionally important in preserving accuracy. Routine calibration makes certain that the testing devices is functioning properly and giving precise analyses. One more means to boost precision and accuracy is through analytical analysis. By applying statistical techniques, such as control graphes and regression analysis, you can determine and get rid of outliers and boost the total dependability of examination outcomes. It is essential to develop standardized screening procedures and protocols. By adhering to regular techniques and standards, you can minimize irregularity and improve the accuracy and precision of screening across various research laboratories and operators.Novel Strategies to Reviewing Product Characteristics

Using advanced methods and approaches, you can improve the assessment of material homes with cutting-edge methods. By employing methods like ultrasonic testing, radiography, and thermal imaging, you can evaluate material residential properties without creating any type of damages.Another unique method is the consolidation of sophisticated computer simulations. Via computational modeling and simulation, you can properly predict material residential or commercial properties and behavior under different conditions. This allows you to enhance product Discover More Here style and performance, leading to the growth of much more reliable and long lasting products.

Moreover, making use of expert system and artificial intelligence algorithms has actually reinvented material home examination. These innovations can assess substantial amounts of information and determine patterns that may not be obvious to human observers. By training formulas on huge datasets, you can develop predictive models that properly approximate material homes based on numerous input parameters.

Additionally, microstructure evaluation methods, such as electron microscopy and X-ray diffraction, provide beneficial insights right into the internal framework of materials (material testing lab). By analyzing the setup of atoms and crystal problems, you can obtain a deeper understanding of material residential or commercial properties and their relationship with performance

Future Trends in Product Testing

By integrating emerging modern technologies and methods, you can stay at the center of material testing innovations and properly assess product properties for future applications. As innovation remains to develop, the field of product screening is also undergoing substantial modifications. One of the future patterns in material screening is making use of innovative computer simulations. These simulations permit researchers to forecast material actions under different problems, reducing the demand for physical testing and saving time and sources. Additionally, there is an expanding concentrate on sustainable and eco friendly products. Material testing laboratories are currently exploring means to analyze the sustainability and recyclability of products, guaranteeing that they meet the demands of a much more eco-conscious culture. An additional arising trend is the assimilation of fabricated intelligence (AI) and artificial intelligence right into product screening processes. AI algorithms can evaluate substantial you could try here quantities of data and determine patterns that people might ignore, causing more reliable and exact material testing results. There is a change in the direction of in situ and real-time material testing. This method enables researchers to keep track of product habits under real operating problems, offering important insights into the efficiency and toughness of products. As product screening proceeds to advance, remaining upgraded on these future fads will certainly be critical for ensuring the development of innovative and dependable materials for different industries.Final Thought

In conclusion, the innovations in material screening methods discussed in this short article emphasize the constant initiatives of leading labs to boost accuracy, accuracy, and efficiency in screening. Non-destructive testing techniques have actually become a beneficial tool, while over at this website unique methods and arising technologies use new possibilities for reviewing material buildings. material testing lab. As innovation proceeds to evolve, we can expect additional developments and future patterns in product testing that will certainly drive innovation and improve our understanding of products

You'll uncover how non-destructive testing has actually advanced, discover arising technologies in material evaluation, and find out about novel methods to reviewing product residential or commercial properties. By the end of this post, you'll have a far better understanding of the cutting-edge methods being utilized in material screening research laboratories, encouraging you with the understanding to make educated choices concerning the products you function with.

Report this wiki page